2.008

Garyo-yo

Design & Manufacturing II - 2.008 - is MIT’s Mechanical Engineering course that focuses on manufacturing systems, design for manufacturing, and process physics & control. The class’ semester-long group project consists of designing a yo-yo for mass production before fabricating the parts necessary for a fifty-unit production run.

Design

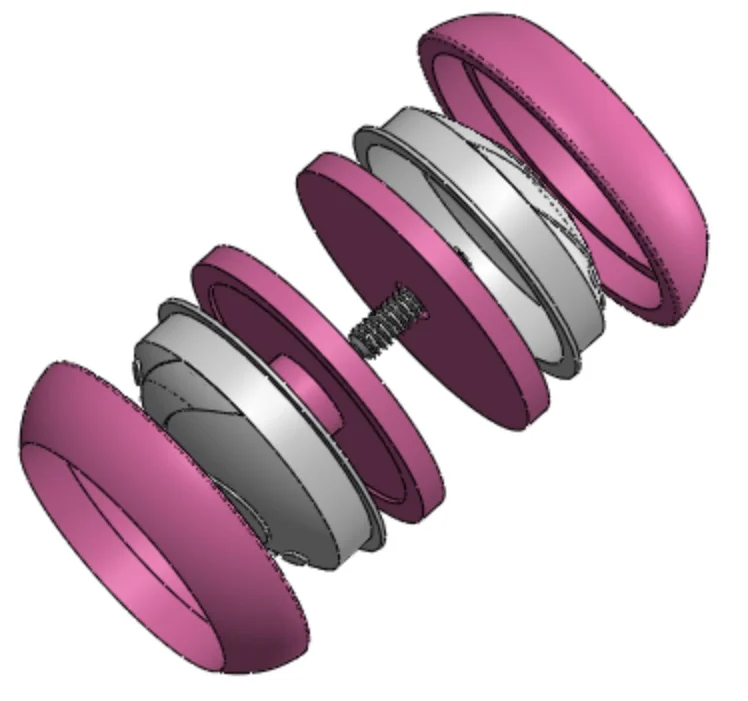

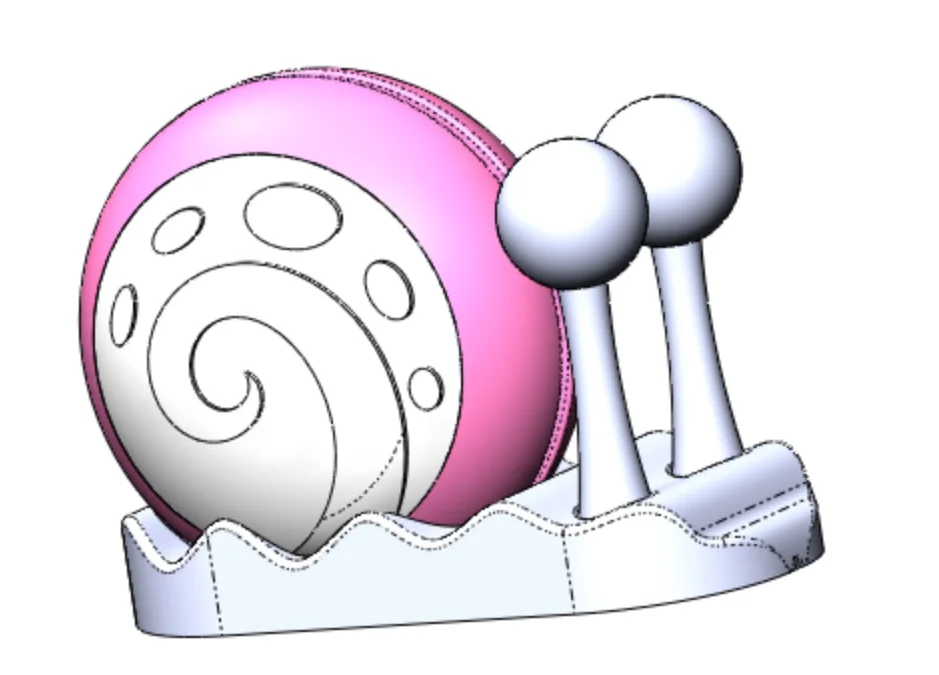

The yo-yo’s design focused on producing a simple yet recognizable design to ensure a high quality assembly throughout the manufacturing run. To achieve this, our 5-person team chose to take Gary the Snail out of Bikini Bottom, bringing him to the classroom at MIT. Spongebob Squarepants’ companion in his pineapple under the sea is composed of three plastic pieces secured by a press fit between the outer retainer ring and the base plate, sandwiching a lip on the middle piece to secure each yo-yo half.

Prototype

Before manufacturing, a prototype yo-yo was 3D printed (via stereolithography) on a Form 2 to validate the feel and functionality of the design. The yo-yo’s dynamics and balance appealed in user testing, allowing the go-ahead for manufacturing.

Manufacturing

The center yo-yo component (with the swirl) and yo-yo base (the snail body) are both thermoformed on 3D-printed molds that were used to overcome a limited tooling capacity. The outer retainer ring, inner base circle, eyes, and eye stalks were each injection molded to complete the production run. Each side of the yo-yo was fastened with a snap fit before the two sides were screwed together, yielding a 3.75 minute assembly time per unit over a 50 yo-yo run.